Just-in-time JIT is a management approach that is used to control the flow of inventory to and from a business in order to minimize inventory levels and to improve the efficiency of the manufacturing processes. The result is a large reduction in the inventory investment and scrap costs though a high level of coordination is required.

𝐉𝐮𝐬𝐭 𝐈𝐧 𝐓𝐢𝐦𝐞 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠 Jit 𝐉𝐮𝐬𝐭 𝐈𝐧 𝐓𝐢𝐦𝐞 Just In Time Inventory Management Youtube

What Is Just In Time Inventory And Benefits Of Jit

Just In Time Inventory Jit Explained A Guide Netsuite

At issue here is a global manufacturing model that focuses on low costs and lean inventory at every step in the chain a model where all the parts arrive at the plant just in time.

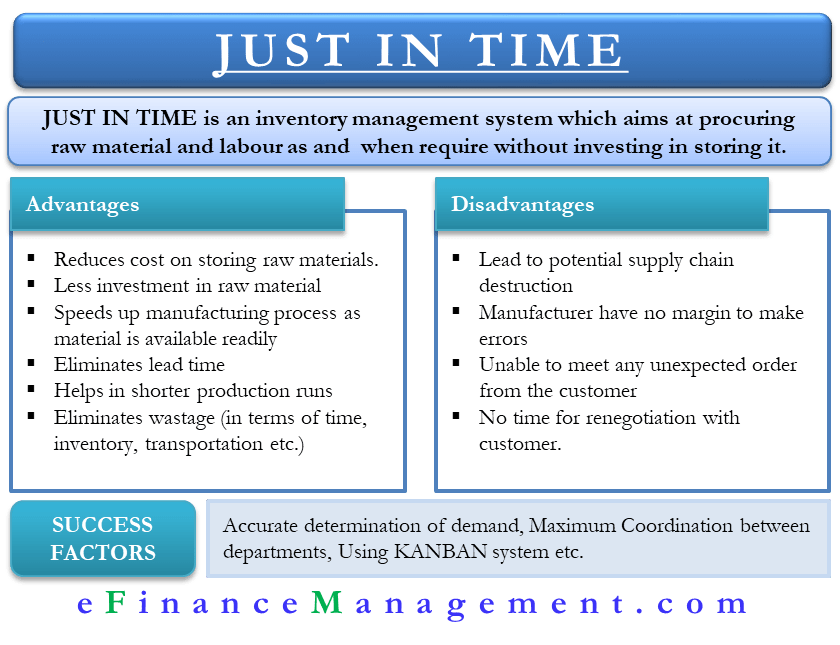

Just in time inventory. JIT Just-in-Time manufacturing Just-in-time is a management philosophy and not a technique. Just-in-time JIT inventory is a stratagem that manufacturers utilize to increase efficiency and decrease waste by receiving goods only as they are needed in the manufacturing process thereby reducing the cost of inventory. JIT methods appear to give the promise of leaner lead times and lower inventory costs.

Just in Time inventory management methodology. Lean inventory management or just-in-time inventory planning has been a way of thinking within the supply chain management world for decades with Toyota often credited with pioneering the method. It is derived from Toyotas 1930 operating model The Toyota Way Toyota Production System TPS.

That means you dont stockpile products and raw materials just in case you need themyou simply reorder products to replace those youve already sold. JIT was originally formed in Japan as a response to the countrys limited natural resources leaving little room for wastage. Wasp inventory software puts a more efficient picking process with mobile barcode scanning to identify picking errors at the source thus eliminating the time spent finding and correcting errors when back at a packing station.

Time to shine or rethink. In the 1970s the Japanese automotive giant Toyota gave the world an efficient and cost-saving management strategy named Just in Time inventoryLike the name suggests the company ordered parts only when it received new car orders. The just-in-time or JIT inventory ordering process has been around since the 1970s but much newer examples show how much more efficiently.

To give a clearer picture the inventory management system developed by Taiichi Ohno a Toyota industrial engineer was aimed at aligning production. The Just-In-Time JIT concept is a manufacturing workflow methodology aimed at reducing flow times and costs within production systems and the distribution of materials. This approach differs from the more common alternative of producing to a forecast of what customer orders might be.

Just-in-time or JIT is an inventory management method in which you keep as little inventory on hand as possible. By calculating that compressed lead time and reducing the cost of carrying a safety stock inventory you will likely come up with an attractive projection. The just-in-time JIT inventory system is a management strategy that minimizes inventory and increases efficiency.

Potential Issues With a Just-In-Time Supply Chain. Just-in-time started as a simple inventory system where you dont store produced items or extra resources needed to produce these items but only produce when there is an actual demand for your products or services. Importantly manufacturers must forecast their requirements accurately.

Definition and explanation. With growing competition and increasing pressure to boost profitability many businesses have adopted this strategy to boost their bottom linewhich can be problematic when supply chains come to a. Just-in-time also known as JIT is an inventory management method whereby labour material and goods to be used in manufacturing are re-filled or scheduled to arrive exactly when needed in the manufacturing process.

Therefore just in time logistics allows supply chain management companies to save on inventory costs and allow more usable space in their warehouses for components that are ordered more variably. JIT refers to a system of manufacturing that lets business owners produce products once a customer has requested and paid for it rather than having already assembled products on. Just-in-time JIT inventory and just-in-time manufacturing have been buzzwords in the world of supply chain for some time now and quite a few businesses have adopted this approach.

It originally referred to the production of goods to meet customer demand exactly in time quality and quantity whether the customer is the final purchaser of the. Faculty using just-in-time teaching often use quotes from students responses to the pre-class assignments as talking points during the class period. Just-in-time manufacturing provides zero tolerance for mistakes as it makes re-working very difficult in practice as inventory is kept to a bare minimum.

These just-in-time adjustments lend their name to the technique just as Just-in-Time business strategies rely on continuous adjustments to parts supplies and product inventory. The strategy is to arrange the orders of raw materials in such a way that the goods are only ordered when required for production. Inventory and non-inventory purchased items and services can be consolidated on a single pick order and provided to inventory pickers to ensure order accuracy.

There is a high reliance on suppliers whose performance is generally outside the purview of the manufacturer. What is Just-in-Time Inventory. Today Just in Time systems are used by many businesses and it has influenced related lean inventory management techniques like IBMs Continuous Flow Manufacturing CFM.

A just-in-time inventory system keeps inventory levels low by only producing for specific customer orders. While just in time delivery enables supply chain companies to reduce their costs for inventory storage and management it does present an alternative challenge of accurately forecasting demand. The Just in Time JIT style of inventory management also sometimes referred to as the Toyota Production System TPS is a strategy of managing inventory Inventory Inventory is a current asset account found on the balance sheet consisting of all raw materials work-in-progress and finished goods that a andor production that links the ordering of raw materials to production scheduling.

The automaker famously redesigned its supply chain after it experienced issues following a 2011 earthquake. The concept was popularized by the productivity of Japanese industry in the early 1970s within the Toyota manufacturing plants that would meet consumer demands with minimum delays using an approach focused on people plants. Just in time JIT inventory control systems occur when a business holds no stock and instead relies upon deliveries of raw materials and components to arrive exactly when they are needed.

Lean manufacturing also known as lean production just-in-time manufacturing and just-in-time production or JIT is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. One of the most popular methods for inventory management is just-in-time JIT manufacturing. Lean inventory management or just-in-time inventory planning has been a way of thinking within the supply chain management world for decades.

Major Benefits Of Just In Time Jit System Qs Study

What Is Just In Time Inventory Management Business Accounting

Just In Time Method Overview How It Works Pros And Cons

The Examples Of Just In Time Jit Inventory Processes

Just In Time Inventory Definition Advantages Examples Video Lesson Transcript Study Com

Just In Time Reduce Waste Improve Your Production Tulip

Advantages And Disadvantages Of Just In Time Inventory

How Different Industries Use Just In Time Inventory Management For Success Montrichard Group